You may remember Earth Day celebrated by your school. On this day, children are taught to plant trees and given lectures about reducing, reusing, and recycling. While most of us remember these activities, it is unfortunate that we have been unable to evolve our understanding of sustainability beyond these activities.

Recycling today has become more complicated than ever, thanks to the production of large amounts of packaging materials that end up in landfills. While recycling facilities are working and new ones are being set up, they are unable to provide a quick remedy to the alarming situation.

With the packaging materials becoming more complex due to their compositions, the recycling requirements have also increased quite a bit. Every packaging material comes with its specific recycling instructions, some of which may not be understandable for most consumers.

The average contamination rate of recyclable packaging supplies is 25%, which means that one in every four packaging products sitting in a recycle bin is not recyclable due to contamination. Accumulation of a lot of contaminated recyclable products can be quite detrimental to the recycling economy.

While most e-commerce consumers now prefer recyclable and sustainable packaging materials, the path to perfection is still not clear.

A more inclusive perception of sustainability

The arrival of a damaged product has become a fairly common instance in the e-commerce world. A more prompt brand would send another product immediately, asking the customer to throw away the damaged one.

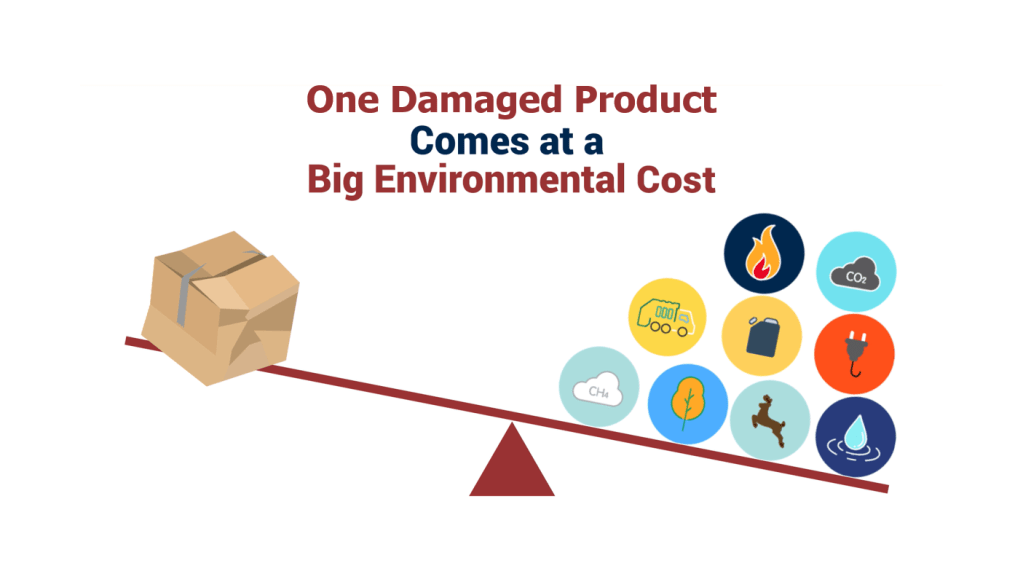

While such instances are undoubtedly undesirable for brands, the larger impact is on the environment due to a considerable amount of waste. The delivery of a damaged item means the product, along with its packaging, going into the trash.

Damaging effects to the planet

While damaged products and packaging are not welcomed anywhere, a lot of products get damaged during shipping. With e-commerce prevailing with every passing day, the instances of product damages are increasing significantly. Furthermore, the concept of product returns has also resulted in a rise in packaging wastes. Consumers, who do not like a product upon delivery, opt to send it back to the manufacturer, throwing its packaging into the trash can.

Wastes due to damaged or returned products are not limited to the packaging supplies only. Every e-commerce product has to travel to its consumer in the first place, which means that it has to be manufactured, stored, packaged, and transported before it reached its destination. Each of these steps results in some form of emissions or energy consumption. That means the environmental impact of the entire supply chain process is more significant than we can imagine. And then product damage or return adds more to this impact and that too quite significantly.

What does all this mean? Well, it means that every product packaging decision has an impact on the environment. That is why it is necessary to be mindful of each step involved in the supply chain. While packaging products, make sure to use enough packaging supplies to protect your product during shipping. However, be sure not to go for overkill. Work on the dimensional weight of all of your packages to keep costs and fuel consumption under control.